具有成本效益的解决方案

当使用离轴抛物镜时,光学设计方案中的许多问题就会被发现。他们能提供在性能无需折中的最低成本解决方案。

OAP有无障碍光圈的优势,在系统设计中可通向焦平面。这会在光轴上产生由支架或者其他障碍物引起的衍射图案。如果要进行MTF或者类似测量时,这个是十分重要的。由于离轴抛物面反射镜具有消色差的特点,因此特别适用于宽带和多波长应用。

应用:

l 准直

l 扩速镜

l FLIR测试

l 高功率激光光束聚焦

l 目标发生器

l MTF参考表面

l MRTD测试系统

l 光谱反射镜

质量和价值

首创制造OAP技术,减少需求,而将投入大量放在复杂固定焦距的父抛物镜上,将其切割制成所要求的镜子。在不考虑成本的情况下,可以为您特制产品以适应您的需要。仅仅当最小规格反射镜(直径小于

反射镜安装

精度和稳定性对于高精度反射镜的使用是十分重要的,并且光学表面公司提供一些万能支架以适合于大多数光学平台的使用。正确安装是避免失真的关键,从我公司订购的镜子在镀膜和安装之后会提供干涉图和OPD图。

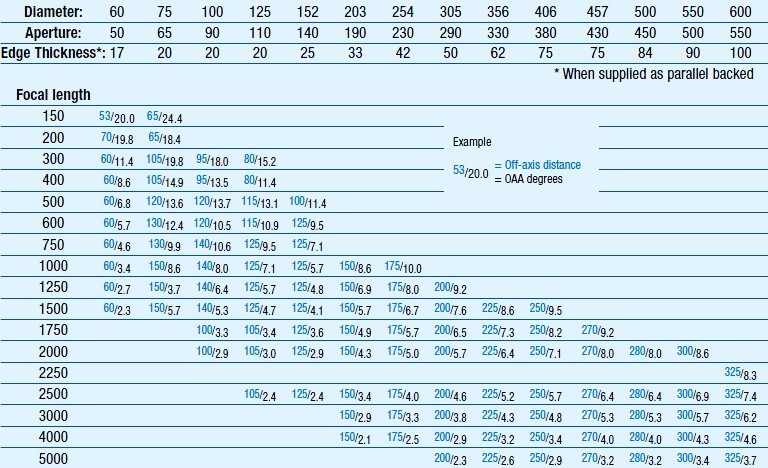

看下面平行光管数据表

注意:

小的机械和光学公差可按要求引用。就如上面所画的示意,

|

直径公差 |

+0/ |

|

厚度公差 |

+0/ |

|

焦距 |

+-1% |

|

离轴距离 |

+ +/ |

|

表面精度 |

λ/10 p-v@633nm(在整个净口径)。坡度误差<λ/10/cm,使用工业级标准软件可提供表征镜子表面精度的干涉图和分析数据。 |

|

微型粗糙度 |

1.2nm有效值。粗糙度的测量不包含在价格当中。 |

|

表面质量 |

60/40 to MIL-O-13830 Rev H 60=60μm and 40= |

|

材质 |

微晶玻璃用于直径等于小于 除非有特殊要求,直径 |

|

镀膜 |

铝和氟化镁包含在标准价格列表。如果在订购时提出,光谱扫描件是免费的。镀银,镀金高功率激光器和飞秒激光器镀膜可根据要求报价。 |

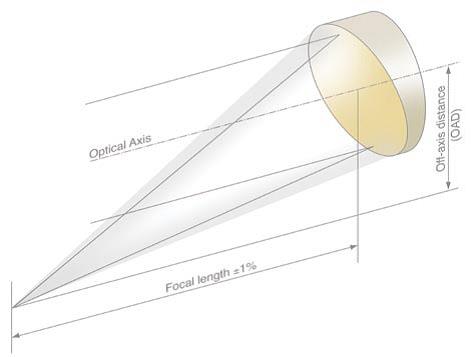

Wedged or Perpendicular Back version Parallel Back option

Wedged or Parallel Back?

We make off axis paraboloids by two distinct methods, giving rise to a choice of physical form shown at left.

Parent method

Generally, OAPs up to

The result of this production method is that the “wedged back” form is the natural choice since the OAP can be directly cut out with a core-drill axis perpendicular to the back.

This form has some advantages: since our parents are made accurately centred, the back can be polished and used to define the optical axis direction. This helps with alignment, and the front of the mirror is already tilted in the correct direction when the back is running square to the customer’s optical table. A mounting groove can be generated in the edge which is often useful to mechanical designers solving the problems of mirror mounting.

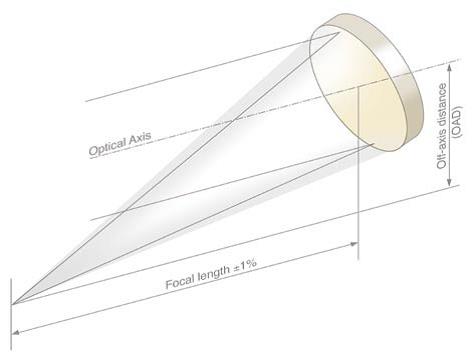

Stand alone method

Mirrors above